Need some advice? Give us a call.

Need some advice? Give us a call.

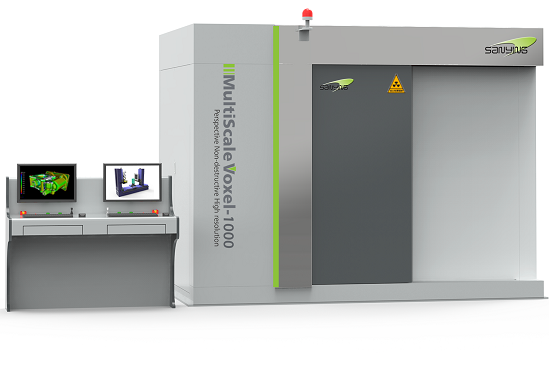

Computed Tomography (CT) is a non-destructive testing (NDT) method for analyzing samples and serves as a key tool for non-destructive evaluation (NDE). It is increasingly replacing traditional destructive sectioning methods.

Computed tomography has gone beyond the conventional boundaries of non-destructive testing. The CT technology used in industrial scanners is tailored to a wide range of industries.

It is a radiological method that uses X-rays to visualize both internal and external structures.

Over time, industrial computed tomography is playing an increasingly important role as a measurement tool. Compared to tactile or optical systems, its advantage lies in capturing data comprehensively and non-destructively.